Integrated Plant (in house induction furnace and rolling mill)

The above helps in achieving a controlled chemistry & superior quality of steel. Certain Alloys are added to further strengthen and enhance the properties of steel. Ultimate Benefit: higher life of steel

Advanced Laboratory & Rolling Mill

For complete testing and creating a high quality standard product. Ultimate Benefit: Only the top quality product is produced.

Fe550D Rebar

The controlled TMT quenching process ensures the standard grade and strength in the rebar. The bar is accompanied by a controlled chemistry & alloys addition to produce the superior grade. Tested and guaranteed Fe 550 D grade ensures safety and helps to save cost because less steel is consumed in this grade. Using SHIVANGI TMT […]

Value For Money

Shivangi Tmt bars are available at economical prices giving the best value to the customers. Ultimate Benefit: Significant savings in the cost of project

Ductility & Easy Bends

With the help of controlled chemistry, tramp elements are reduced and addition of alloys increases ductility in steel. Also using the quenching process in the Thermo Mechanically Treated Bar (TMT) the soft inner layer gives the rebar a bend ability and hence provides better ductility. This can be verified through the elongation test. Ultimate Benefit: […]

Low Tramp Elements

Minimum tramp elements both ferrous and non-ferrous are minimum due to the use of processed iron ore for producing clean steel.

Weldability

Superior weld-ability attained because carbon is in the ideal range. Also because the brittle sulphur and phosphorous are under control, tendency of weld to crack is little. Ultimate Benefit:: Ease of use on site

Yield Stress & UTS & Elongation

Better than BIS standard due to lower tramp elements and controlled chemistry of melt. Also due to ideal inner and outer ring in the tmt bar, the bar is ductile as well as strong. Therefore, elongation is 18% which is ideal for FE 550 D grade.

Uniform ribs & lugs

Using CNC machine to create top notch finish during the rolling process Ultimate benefit: Better reinforcement grip.

Corrosion Resistance

Existence of rust weakens the steel over time. Since the TMT bars have better resistance along with the use of cleaner steel, this aging is highly reduced. compared to regular or substandard bars. Ultimate Benefit: higher life of rebar

Fire Resistance

SHIVANGI TMT BARS have high thermal stability and can counter temperature up to 400 to 600 degree Celsius.

Benefits of Shivangi TMT

FE 500D Rebar

Integrated Plant (in house induction furnace and rolling mill)

The above helps in achieving a controlled chemistry & superior quality of steel. Certain Alloys are added to further strengthen and enhance the properties of steel.

Ultimate Benefit: Higher Life of Steel

Advanced Laboratory & Rolling Mill

For complete testing and creating a high-quality standard product.

Ultimate Benefit: Only the Top-Quality Product is Produced.

FE 500D Rebar

The controlled TMT quenching process ensures the standard grade and strength in the rebar. Tested and guaranteed FE 500D grade ensures safety and helps to save cost because less steel is consumed in this grade. Using SHIVANGI TMT FE 550D Rebars instead of the regular Fe 415 untested grade available in the market, can save up to 15 – 18% in the total cost of construction.

Ultimate Benefit: Highest Strength & Low Cost

Value For Money

Shivangi TMT FE 500D Rebars are available at economical prices giving the best value to the customers. The length of Shivangi TMT FE 500D Rebar is 40 feet. Whereas the length of other branded TMT Bar is 39.37 feet.

Ultimate Benefit: Significant Savings in the Cost of Project

Ductility & Easy Bends

With the help of controlled chemistry, tramp elements are reduced and addition of alloys increases ductility in steel. Also using the quenching process in the Thermo Mechanically Treated Bar (TMT) the soft inner layer gives the rebar a bend ability and hence provides better ductility. This can be verified through the elongation test.

Ultimate Benefit: Earthquake Resistance & Ease of Use on Site

Low Tramp Elements

Minimum tramp elements both ferrous and non-ferrous are minimum due to the use of processed iron ore for producing clean steel.

Weldability

Superior weld-ability is attained because carbon is in the ideal range. Also because the brittle sulfur and phosphorous are under control, the tendency of weld to crack is little.

Ultimate Benefit: Ease of Use on Site

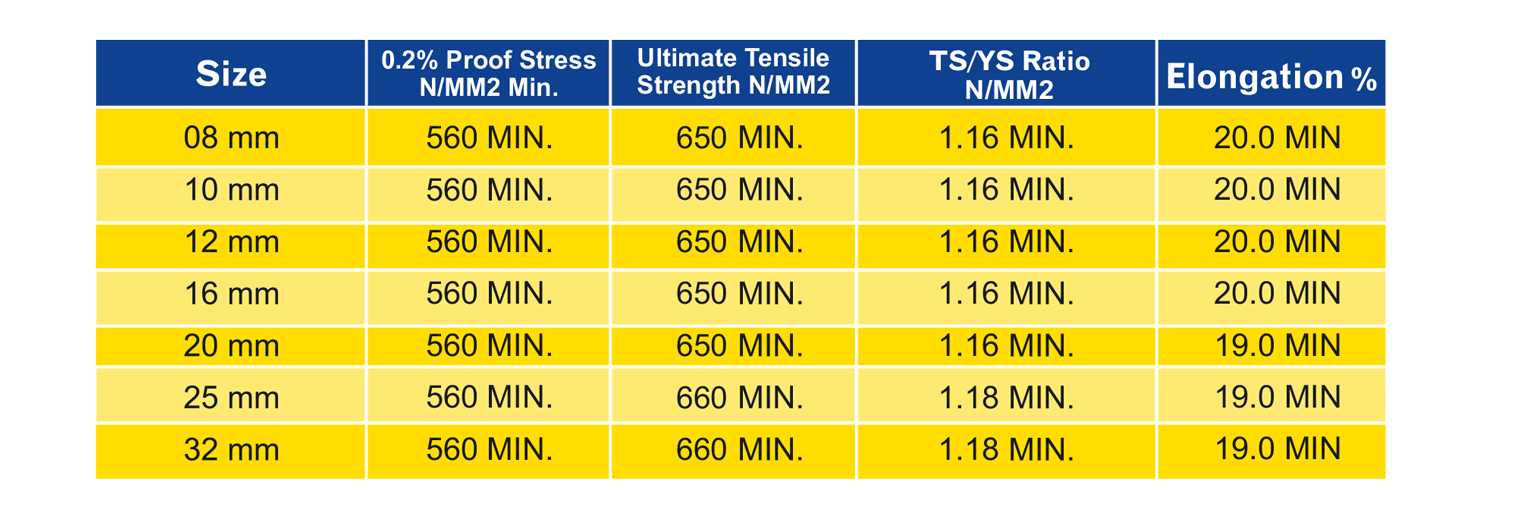

Yield Stress & UTS & Elongation

Better than BIS standard due to lower tramp elements and controlled chemistry of melt. Also due to ideal inner and outer ring in the TMT bar, the bar is ductile as well as strong. Therefore, elongation is 18% which is ideal for FE 500 D Rebar grade.

Uniform Ribs & Lugs

Using CNC machine to create top notch finish during the rolling process

Ultimate benefit: Better Reinforcement Grip.

Corrosion Resistance

Existence of rust weakens the steel over time. Since the TMT Bars have better resistance along with the use of cleaner steel, this aging is highly reduced compared to regular or substandard bars.

Ultimate Benefit: Higher Life of Rebar

Fire Resistance

SHIVANGI TMT FE 500D Rebar have high thermal stability and can counter temperature up to 400 to 600 degree Celsius.

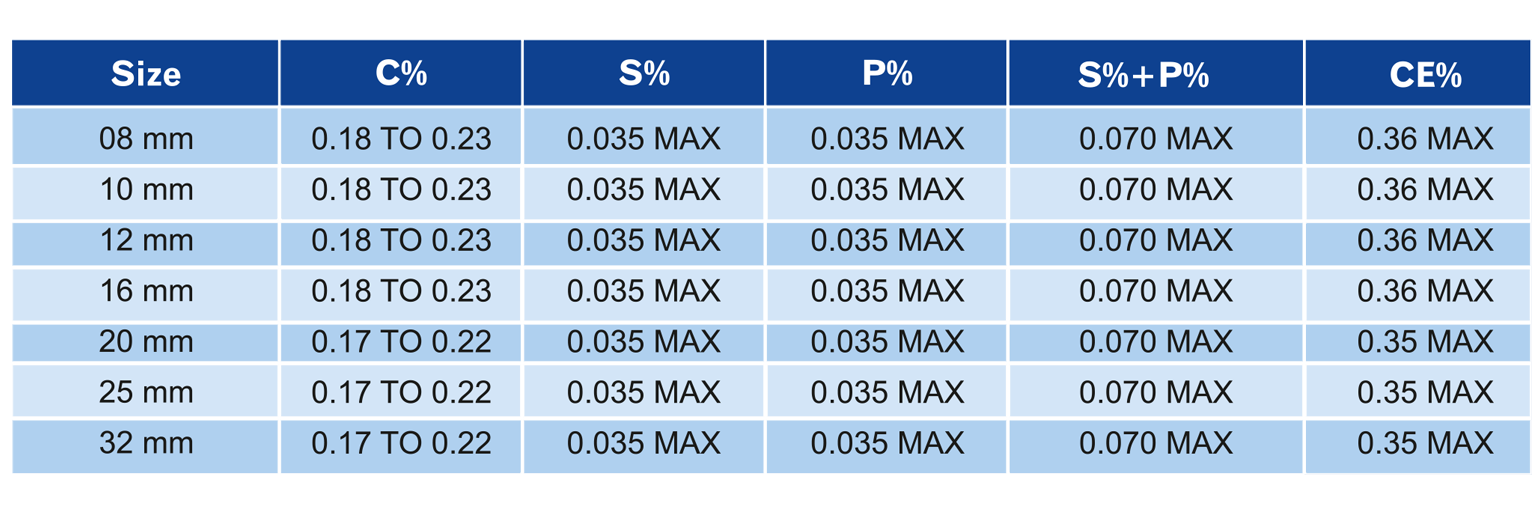

Chemical Properties of Shivangi TMT FE 500D Rebar

| CHEMICAL PROPERTIES | SHIVANGI Fe500 | BIS Fe 500 |

|---|---|---|

| Carbon | 0.20 to 0.27 | 0.3 max |

| Carbon Equivalent | 0.32 to 0.38 | 0.42 |

| Sulphur | 0.40 | 0.55 max |

| Phosphorous | 0.5 | 0.55 max |

Physical Properties of Shivangi TMT FE 500D Rebar

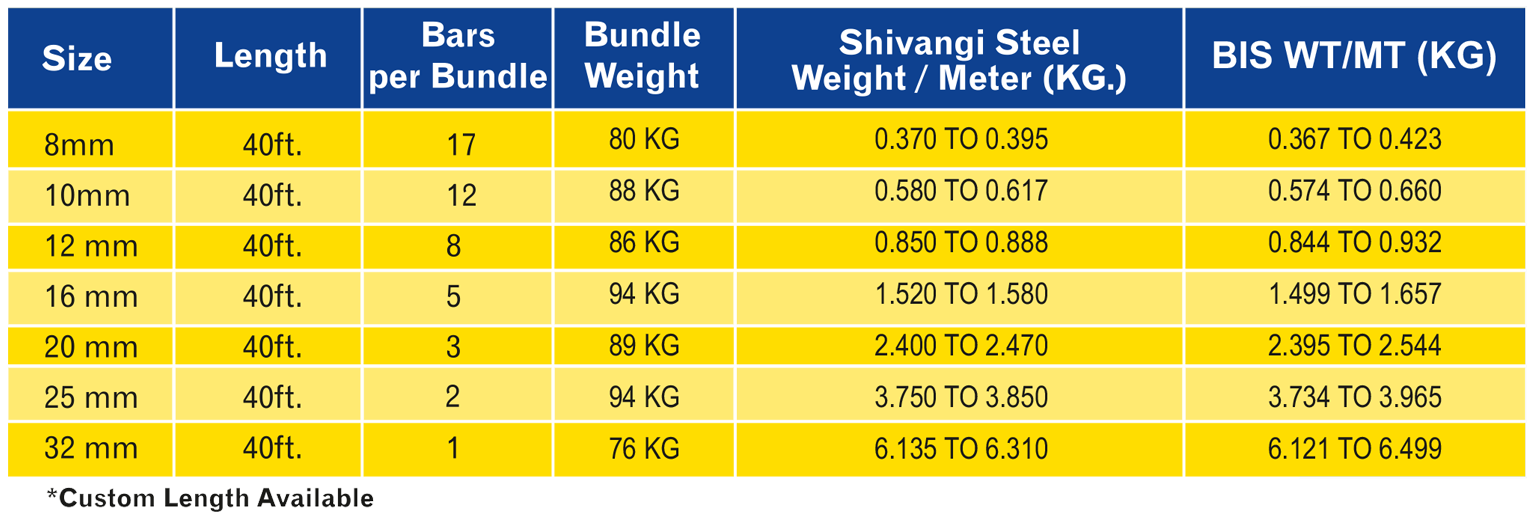

Shivangi TMT FE500D Rebar - Bundle Specification

Benefits of Shivangi TMT Bar

Integrated Plant

(in house induction furnace and rolling mill)

The above helps in achieving a controlled chemistry & superior quality of steel. Certain Alloys are added to further strengthen and enhance the properties of stee

Ultimate Benefit: higher life of steel

Advanced Laboratory & Rolling Mill

For complete testing and creating a high quality standard product

Ultimate Benefit: Only the top quality product is produced.

Fe550D Rebar

The controlled TMT quenching process ensures the standard grade and strength in the rebar. The bar is accompanied by a controlled chemistry & alloys addition to produce the superior grade. Tested and guaranteed Fe 550 D grade ensures safety and helps to save cost because less steel is consumed in this grade. Using SHIVANGI TMT Fe 550D re-bars instead of the regular Fe 415 untested grade available in the market, can save up to 15 – 18% in the total cost of construction.

Ultimate Benefit: Higher strength & low cost

Value For Money

Shivangi Tmt bars are available at economical prices giving the best value to the customers

Ultimate Benefit: Significant savings in the cost of project

Ductility & Easy Bends

With the help of controlled chemistry, tramp elements are reduced and addition of alloys increases ductility in steel. Also using the quenching process in the Thermo Mechanically Treated Bar (TMT) the soft inner layer gives the rebar a bend ability and hence provides better ductility. This can be verified through the elongation test

Add Your Heading Text HereUltimate Benefit: Earthquake resistance & ease of use on site

Low Tramp Elements

Minimum tramp elements both ferrous and non-ferrous are minimum due to the use of processed iron ore for producing clean steel.

Weldability

Superior weld-ability attained because carbon is in the ideal range. Also because the brittle sulphur and phosphorous are under control, tendency of weld to crack is little

Ultimate Benefit:: Ease of use on site

Yield Stress & UTS & Elongation

Better than BIS standard due to lower tramp elements and controlled chemistry of melt. Also due to ideal inner and outer ring in the tmt bar, the bar is ductile as well as strong. Therefore, elongation is 18% which is ideal for FE 550 D grade.

Uniform ribs & lugs

Using CNC machine to create top notch finish during the rolling process

Ultimate benefit: Better reinforcement grip.

Corrosion Resistance

Existence of rust weakens the steel over time. Since the TMT bars have better resistance along with the use of cleaner steel, this aging is highly reduced. compared to regular or substandard bar

Ultimate Benefit: higher life of rebar

Fire Resistance

SHIVANGI TMT BARS have high thermal stability and can counter temperature up to 400 to 600 degree Celsius.